Average Ductility Of A Sheet Of Stainless Steel

There are many grades within each stainless steel category and different grades have different characteristics such as increased corrosion resistance or greater ductility.

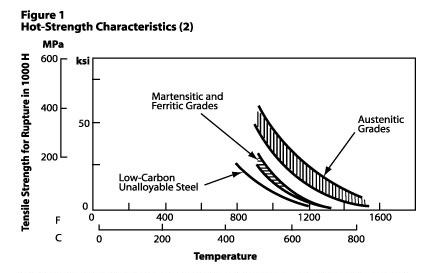

Average ductility of a sheet of stainless steel. Aisi 304 304l astm a240 ams 5513 5511. Strength yield strengtyield strength is the most common property that the designer will need as it is the basis used for most of the rules given in design codes in european standards for structural carbon steels including weathering steel the primary designation relates to the yield strength e g. Grade data specifications and properties are inlcuded for stainless steel. This is generally reported as el or percent elongation.

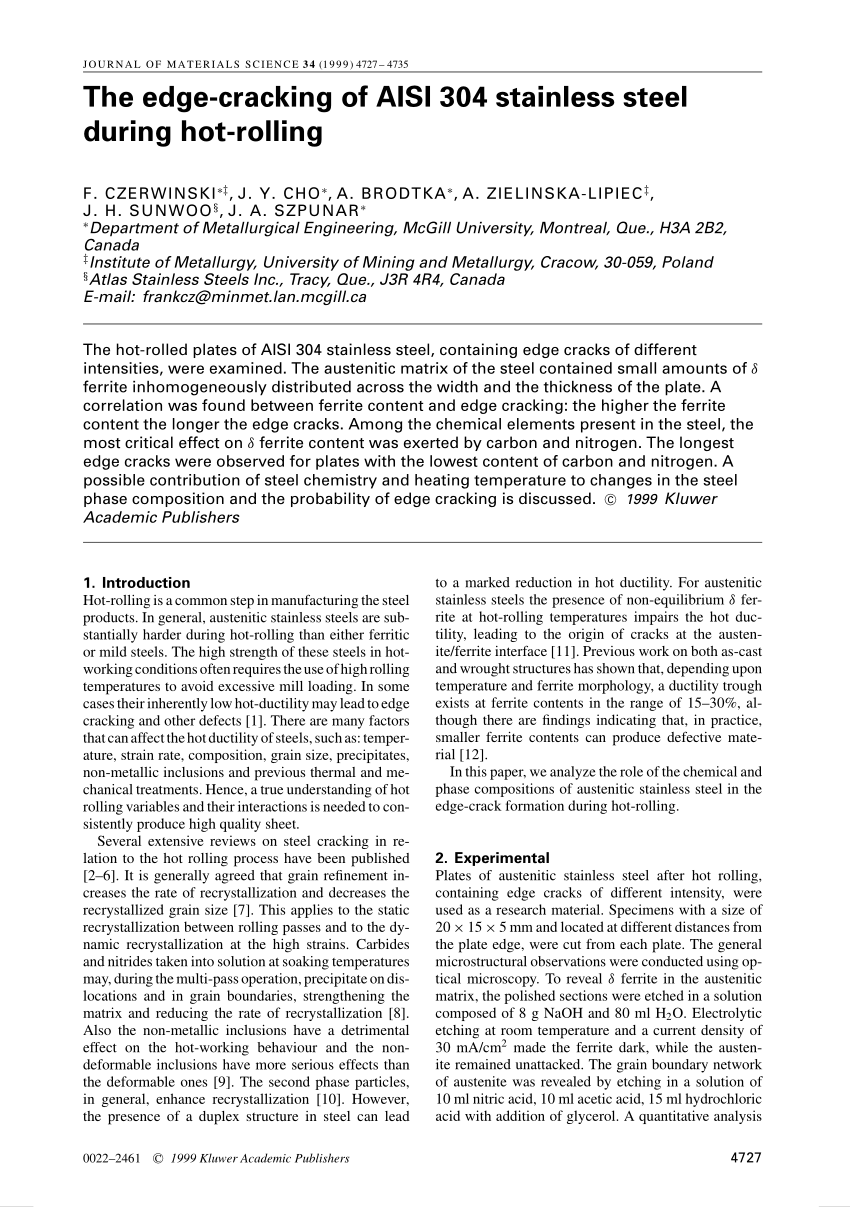

316 316l stainless steel sheet is a popular grade of stainless where superior corrosion resistance is of primary importance. Figure 1 shows equiaxed austenitic grains and significant amount of annealing twins in its as received state. The grain size distribution is presented in fig. Its chemical composition is listed in table 1.

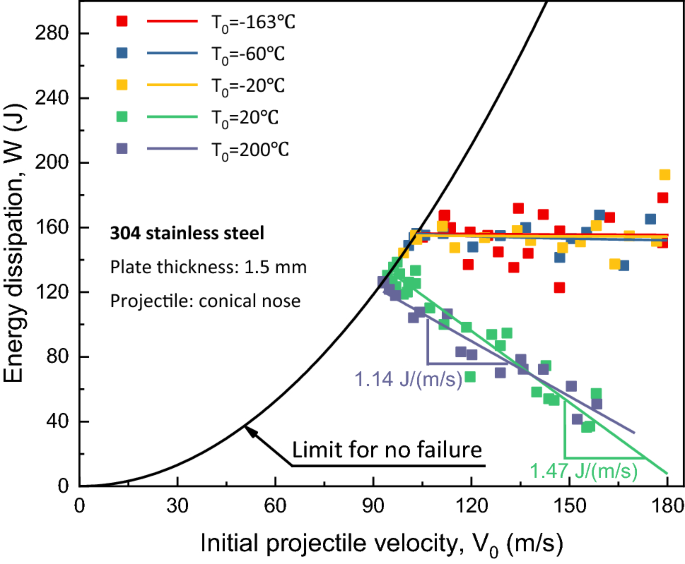

S355 steel is a structural steel with a specified minimum yield strength of 355 n mm. The term stainless steel is used to describe a family of about 200 alloys of steel with remarkable heat and corrosion resistance properties. In each batch two stainless steel grades including grades 304 and 316l were considered and were provided in 1220mm by 2200mm sheets with nominal thicknesses. 304 stainless steel sheet is the most popular and economical of the stainless steels.

The most common measure of ductility is the percentage of change in length of a tensile sample after breaking. The carbon percentage can range from 0 03 to 1 2. Cold work effect on stainless steel corner mechanical properties 0 100 200 300 400 500 600 0 0 005 0 01 0 015 0 02 nominal strain virgin material corner material increase in the 0 2. 304 stainless sheet offers good corrosion resistance to many chemical corrodents as well as industrial atmospheres and marine environments.

304 stainless sheet may become slightly magnetic when worked and is not heat treatable. Ductility is a measure of how much deformation or strain a material can withstand before breaking. 316 stainless sheet is widely used in marine and highly acidic environments underwater equipment surgical tools food and pharmaceutical applications the addition of molybdenum increases the corrosion resistance of 316 stainless over the more economical 304 grade. The name stainless steel covers a variety of corrosion resistant steels.

Stainless steel sheet with a thickness of 10 mm. Let s compare the effect of two grades with different ductility starting with 301 stainless steel and 305 stainless steel. Its distinguishing characteristic is the high amount of chromium. Were considered with their nominal values.