Automated Process Planning For Sheet Metal Bending Operations

This process planning system employs a distributed plan ning architecture.

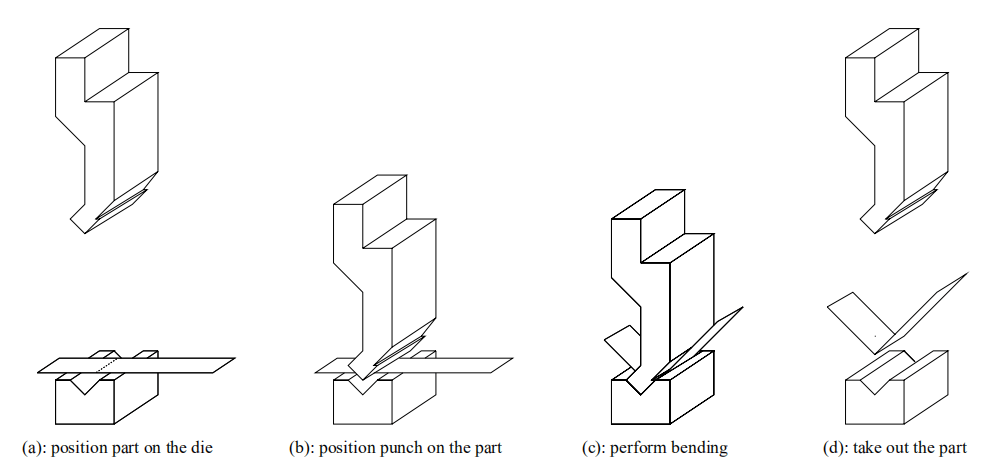

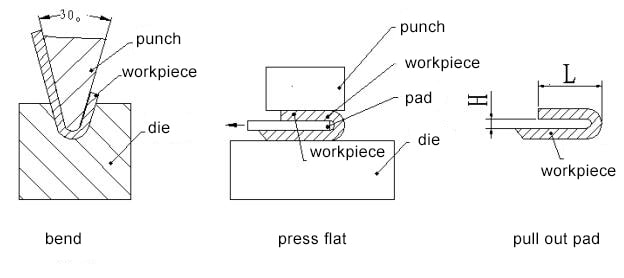

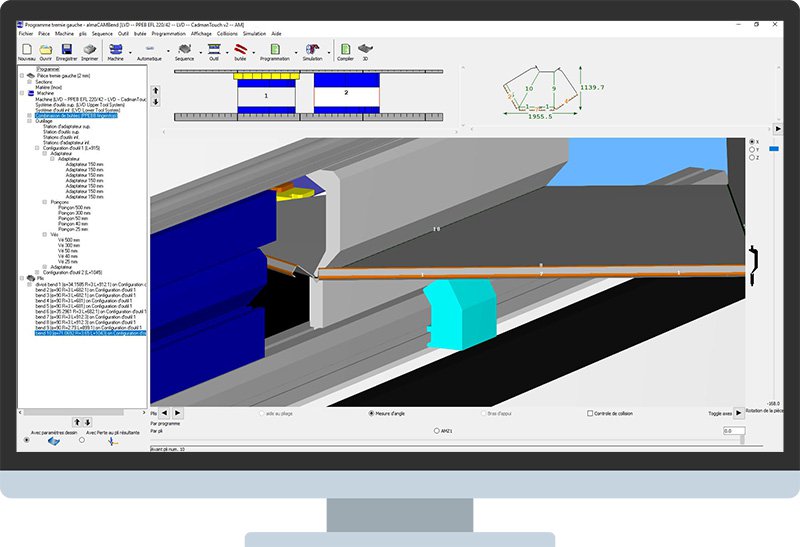

Automated process planning for sheet metal bending operations. Tooling grasping and moving. Currently our system consists of a central operation planner and three specialized domain specific planners. It is a type of bending operation in which a piece of sheet metal is fixed or held between two dies from one end as shown in the fig. Krishnan rapid man ufacturing lab oratory rob otics institute carnegie mellon univ ersit y pittsburgh p a 15213 abstract in this pap er w e describ e a generativ e pro cess planning system for rob otic sheet metal b ending press brak es.

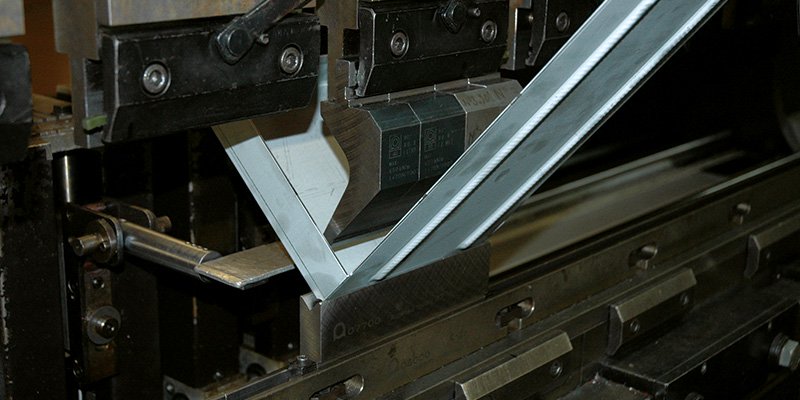

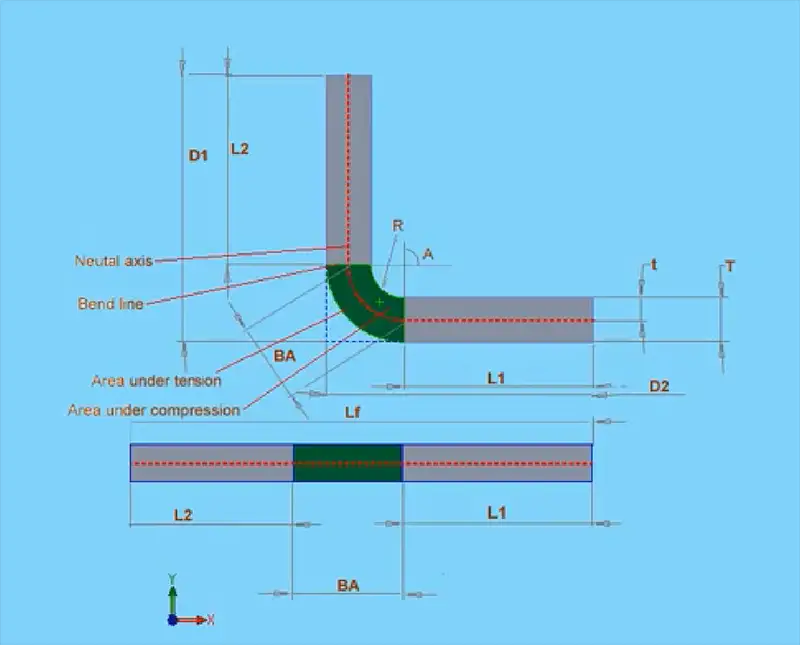

In this paper we describe a generative process planning system for robotic sheet metal bending press brakes. Given a cad file for the desired part the system generates the instructions for driving all components of the robotic press brake which includes a material handling robot a gaging system and an nc press brake. Automated cnc bending lines are suitable for low medium and high volume rectangular sheet metal components. Currently our system consists of a central operation planner and three specialized domain speci c planners.

Then the other end is forced to strike upon the punch which is free or unfixed. Tooling grasping and moving. This process planning system employs a distributed planning architecture. Automated process planning for robotic sheet metal bending.

Tooling grasping and moving. Abstract this paper describes a generative process planning system for robotic sheet metal bending press brakes. This process planning system employs a distributed planning architecture. This process planning system employs a distributed planning architecture.

Abstract this paper describes a generative process planning system for robotic sheet metal bending press brakes. Currently the system consists of a central operation planner and three specialized domain specific planners. Currently the system consists of a central operation planner and three specialized domain specific planners. Thus the free or unfixed edge of the sheet metal piece is bent to make the forming process.

In this paper we describe a generative process planning system for robotic sheet metal bending press brakes. Summary this paper describes a completely automated process planning system for a robotic sheet metal bending press brake. Planning of an appropriate bending sequence is one of the most important aspects in the processing of sheet metals as the appropriateness of the plan affects correct selection of bending tools and feasibility of bending processes. They are widely used in the commercial and residential appliance steel office furniture hvac lighting electrical enclosure telecommunications equipment laboratory and scientific equipment kitchen equipment vending machine and contract manufacturing industries.