Attaching Pieces Of Brass Metal Sheet

The md building products 36 in.

Attaching pieces of brass metal sheet. In this case i m soldering a copper reducer to a piece of copper pipe. Soldering is one method that is widely used to accomplish this. Mill aluminum union jack style perforated sheet metal offers a decorative way to complete your hvac door window hobby and cabinet projects. Open the product cap and apply metal glue to the prepared surface.

The glue most suited for gluing brass to surfaces is 2 part epoxy polyepoxide. There are many brands of glue to choose from which are readily available at hardware stores and supermarkets. Adhesives for example have been known to fail especially when heat or vibration are present. Brass is a metal.

The technique of joining metal pieces is as simple as applying the glue to the surface of the metal where it needs to be joined from pressing the metals together and letting it dry in most cases the pieces to be glued have to be under pressure after clue is applied until it is dry. The metals most commonly joined using tabs are soft steel aluminum copper and brass. Hillman 12 in x 24 in cold rolled steel expanded sheet metal. The sheet features a union jack style perforated design.

X 36 the md building products 36 in. However finding a suitable fastening approach has not been easy. Follow the instructions on the packaging for amounts. When you need to glue brass be sure not to choose a glue that is brittle or that expands.

Thin sheet metal is a popular choice for use in packaging because it is lightweight and takes up less space. For the best results parts should be designed to bend perpendicularly to the direction of sheet rolling or. And sheet metal screws or loose. I use a paste flux which is self cleaning although you should still wipe it with some isopropyl alcohol afterwards.

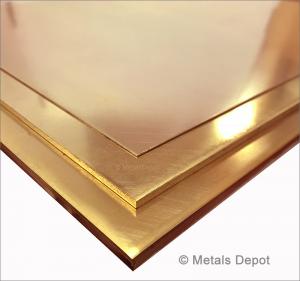

For pricing and availability. Hillman 12 in x 24 in copper decorative sheet metal. It is easy to work with and very attractive in the home. Hillman 24 in x 36 in steel solid sheet metal.

Many epoxy metal glues require mixing adhesive and hardener components then applying with a specialized tool. Bonding metals to each other is a common task in both home based diy projects and commercial production. Welding can be dirty and time consuming. Place the 2 pieces of copper brass you want to solder on a hard surface.

Soldering glues the pieces of metal together by melting a softer metal to act as an adhesive. From time to time you may need to fasten two or more pieces of metal together without bolting soldering or welding them. Glues for homeowners needing to bond metal to metal fall into three general types epoxy polyurethane and cyanoacrylate products. For pricing and availability.

Make sure that you add some flux to the area to be soldered. Which glue is best.