Ansi Sheet Metal Tolerances

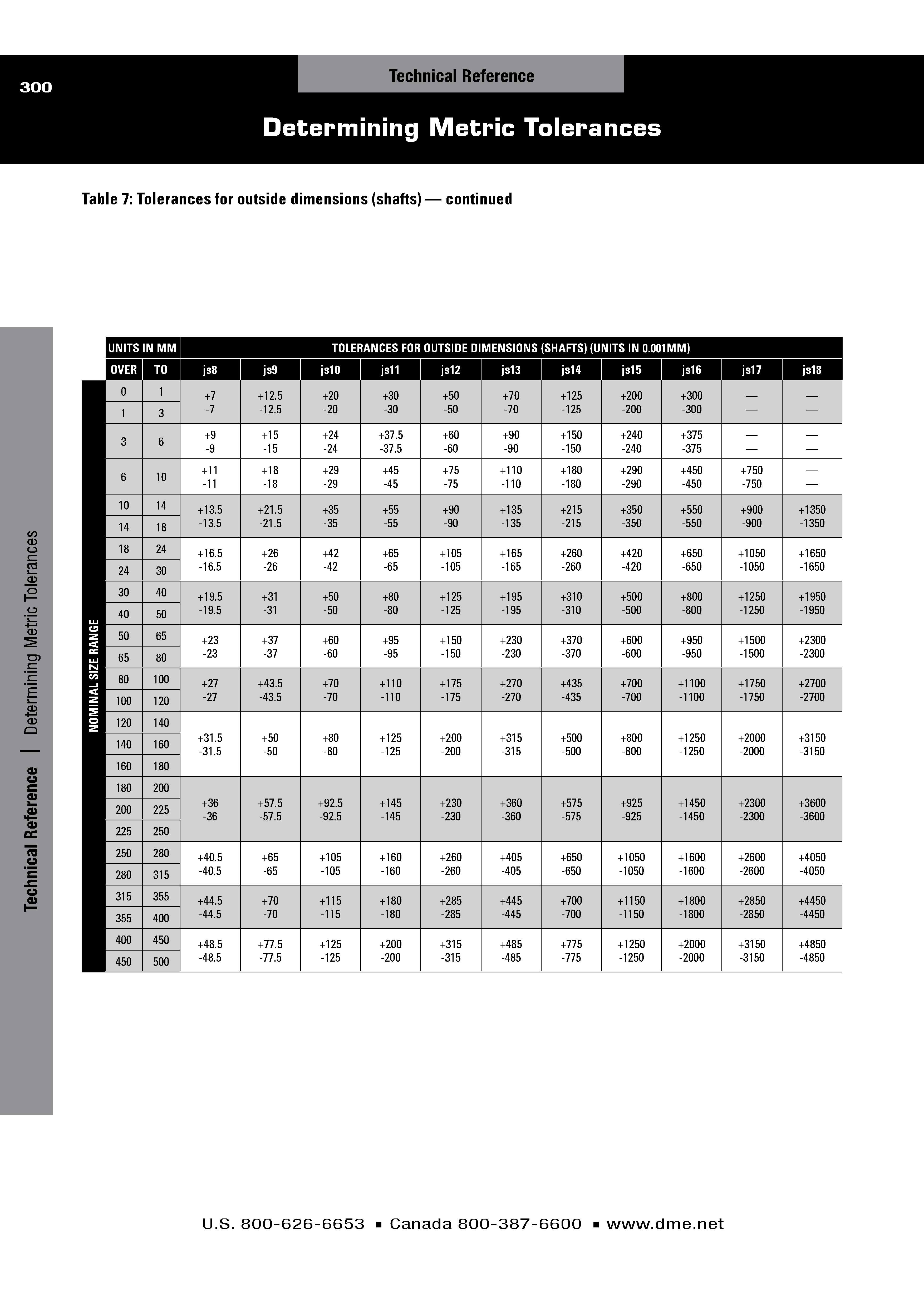

Astm aisi thickness tolerance ranges 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 gage no.

Ansi sheet metal tolerances. Ft 2242 9 375 2092 8 75 1943 8 125 1793 7 5 1644 6 875 1495 6 25 1345 5 625 1196 5 0 1046 4 375 0897 3 75 0747 3 125 0673 2 812 0598 2 5 0538 2 25 0478 2 0 0418 1 75 0359 1 5. Specified width ft. General tolerance iso 2768 does not specify where to use these tolerances. Sms is not responsible for distortion of internal features inside bend areas.

H r p o thickness inches toler range lbs. Conversion of degrees to inches degrees surface width 1 4 1 2 3 4. During the rolling process the rollers bow slightly which results in the sheets being thinner on the edges. And for machined components iso 27 68 fh can be used.

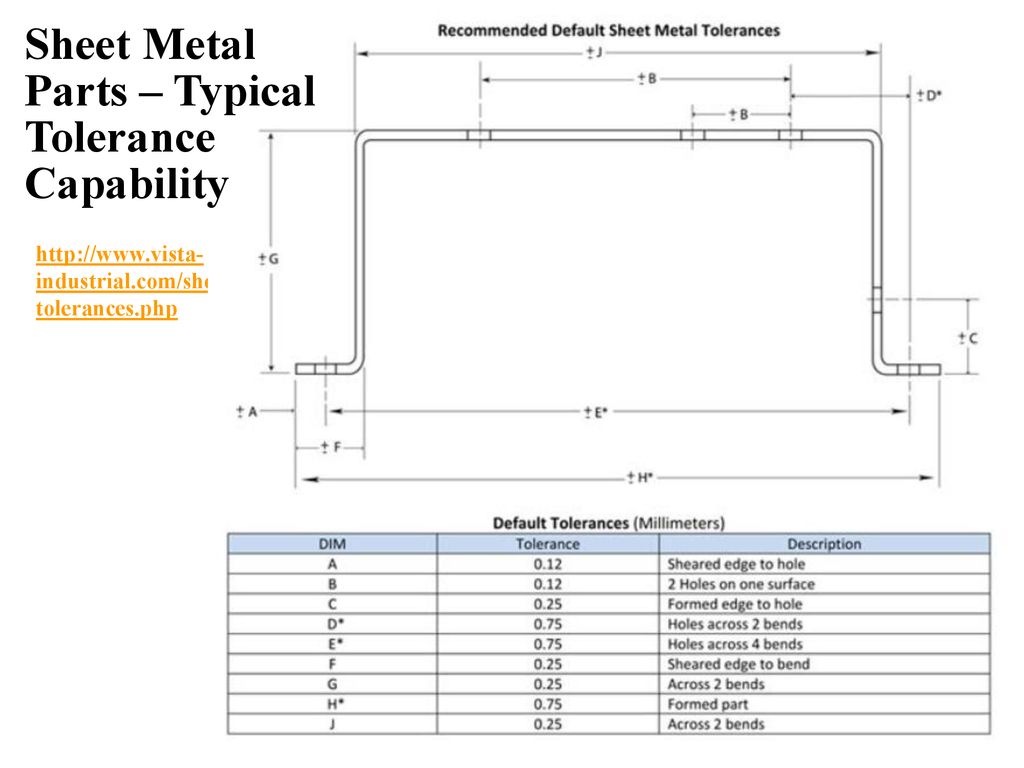

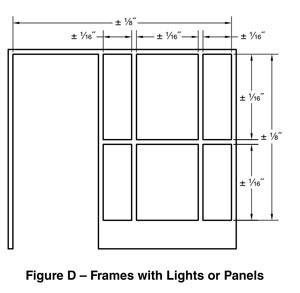

Sheet and plate lateral bow and squareness tolerances lateral bow tolerances flat sheet and plate 1 also applicable to any 240 inch increment of longer sheet or plate squareness tolerances flat sheet and plate specified length ft. The resulting bend angle variation and sometimes the required adjustment to the flat layout contributes to the reason that machined parts typical tolerance of 0 002 in can routinely have tighter tolerances than precision sheet metal parts typical tolerance of 0 010 in. Panel camber and or sweep shall not be greater than 1 4 inch in a 10 foot length 6 mm in 3 m. As per design requirements and manufacturing capability tolerance class is defined.

Degrees tolerance times 0175 times the width of the surface section is being checked on. Uncontrolled dimensions contain two different categories of tolerances. Panel cover width shall be no less than 3 8 inch 10 mm less than the specified panel width nor more than 3 4 inch 19 mm greater than the specified width. 1 all manufacturing tolerances used up to that point such as laser cutting tolerances welding tolerances and more 2 all bend tolerances for the entire part added together we call this an uncontrolled dimensions because there are additional tolerances to consider.

Tolerances apply to any sheet metal product 0 024 to 0 194 thick 2. The tolerances in the table and attachments reflect current manufacturing practices and commercial standards and are not representative of the manufacturer s standard gauge which has no inherent tolerances. Applies to all internal features applies to flat part length up to 24 00. Sheet metal guage tolerances.

Dimensional tolerances only apply to part in constrained state 3. Up thru 3 over 3 allowable difference in length of diagonals inches. The following charts give typical astm and ansi steel sheet mechanical tolerance ranges.