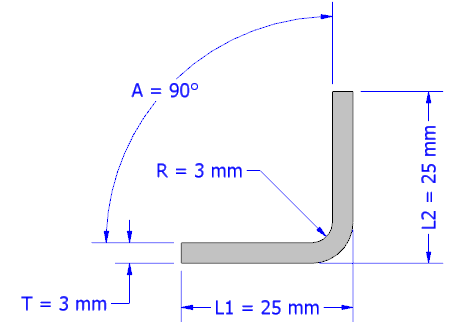

Aluminum Sheet Metal Bend Radius Chart

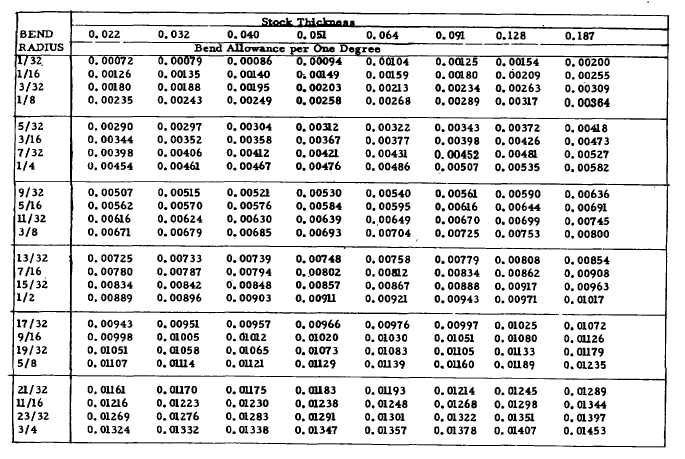

Bend allowance mild sheet steel 90 degree bend allowance.

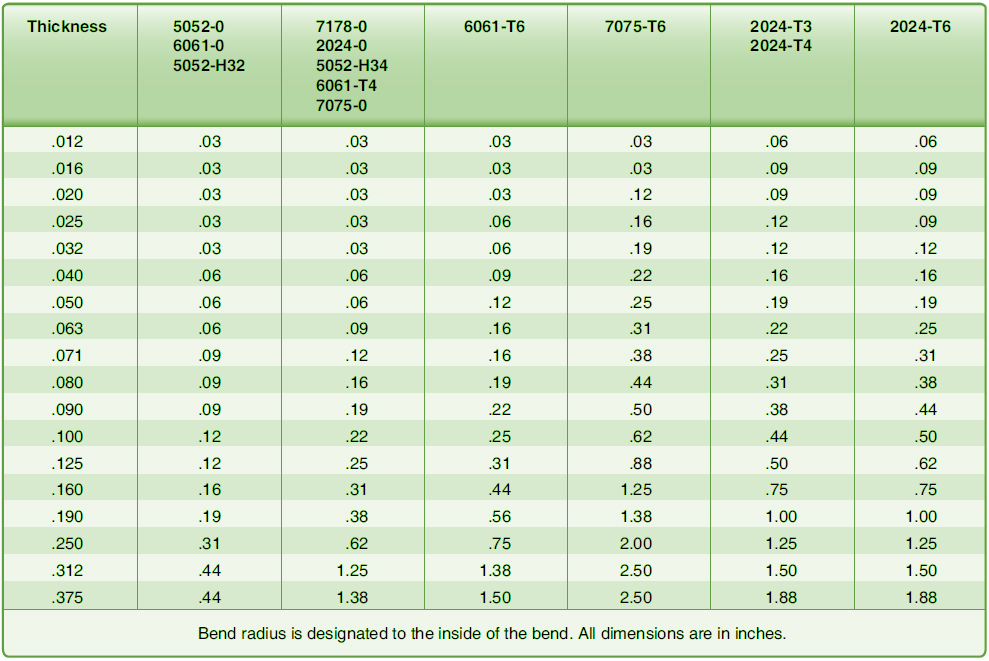

Aluminum sheet metal bend radius chart. Preferred recommended 90 degree bend radii for various sheet metals. To use the tables below. This free chart outlines what bend radii is required for the approximate thickness of aluminum. 032 18 ga 040 16 ga.

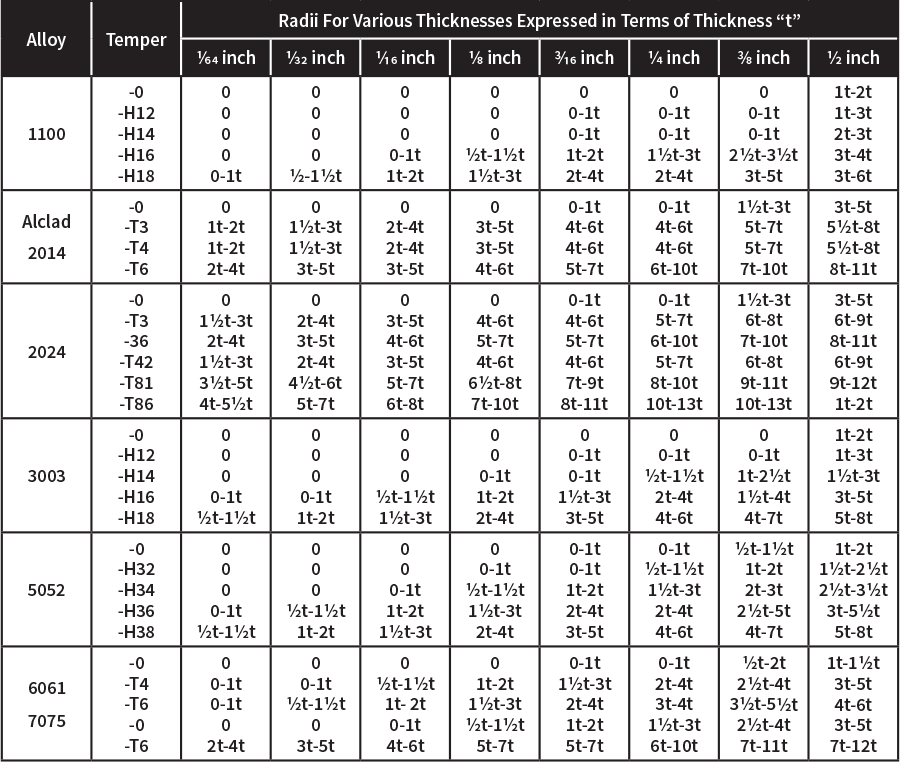

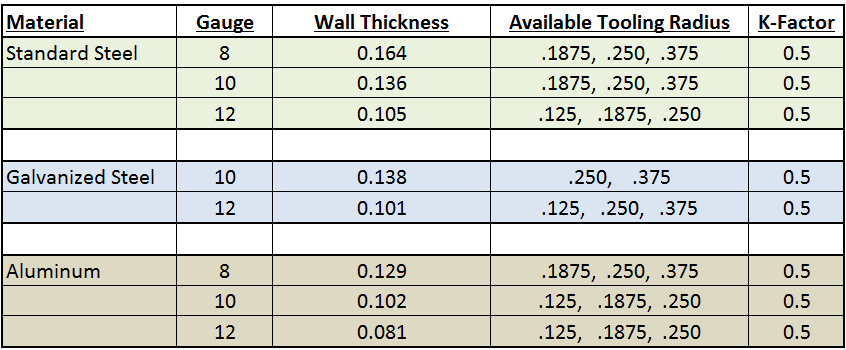

Steel american iron and steel institute. We recommend printing it out to keep as a reference. If these guidelines are not followed more research and or some form of analysis may be requried. Material bend radii and minimum bend size charts please note.

Sheet metal bend radii. When working with aluminum over sheet metal several variables need to be considered. It is possible to choose other bends if you require but additional lead time and tooling charges may apply. Since commercial sheet metal bending can be done with less concern for stresses caused during forming operation the radius can be near zero for thin sheet metal.

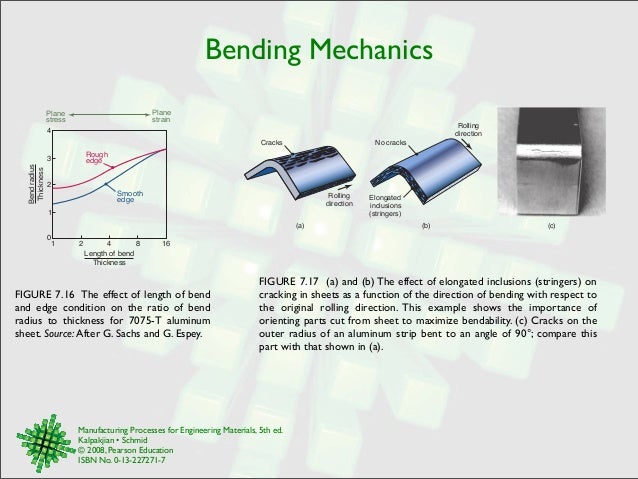

The bend radii listed are standard minimum if manufacturing for aircraft and aerospace applications. Where necessary 5052 h32 may be bent to 1t and 6061 t6 to 1 1 2t. Aluminum is typically thicker and stronger and requires more force to bend as well as consideration of edge conditions and punch nose radii. Refer to table s for your choice of material.

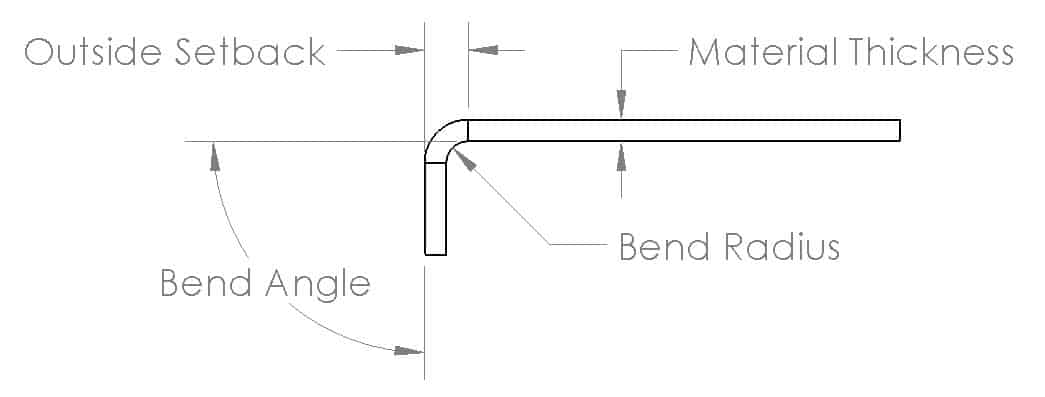

The minimum bend radius data shown in these charts is measured to the inside of the bend. We go beyond the general rules of sheet metal bending as our customers want tight bend radii for sheet metal parts.