Aluminum Grade For Sheet Metal

It can be drawn or formed easily into intricate forms.

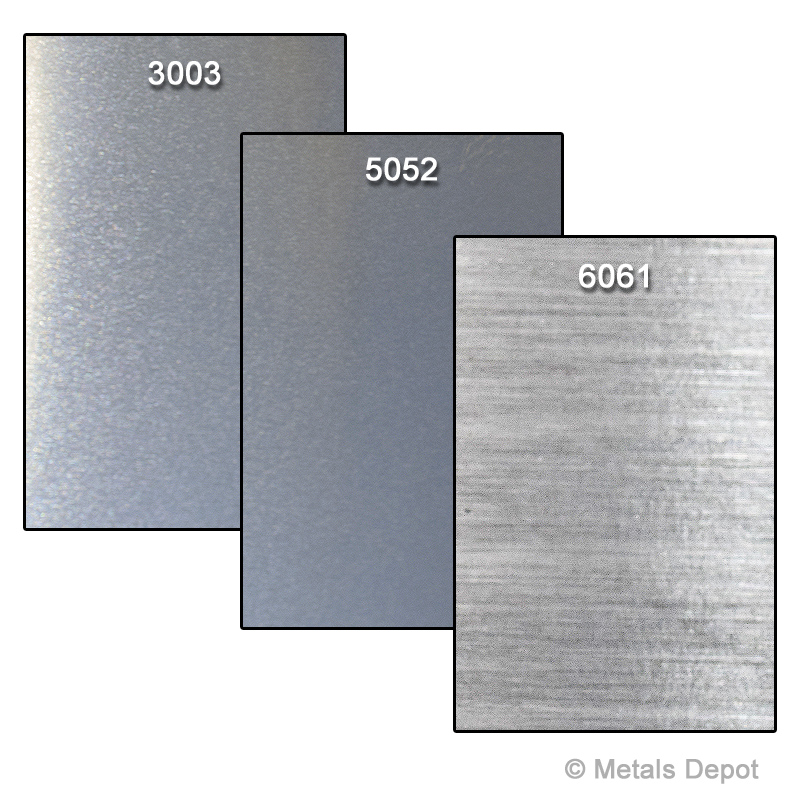

Aluminum grade for sheet metal. Buying the right grade of aluminum sheet metal. There are at least 13 commonly employed types of aluminum and aluminum alloy sheet metal. This is the highest strength alloy of the more non heat treatable grades. Used for drawing spinning fuel tanks and sheet metal work.

5052 aluminum is the highest strength alloy of the more non heat treatable grades. Other popular grades of aluminum alloys include alloy 6063 an architectural alloy and alloy 7075 one of the maximum strength aluminum alloys currently available. A commercially pure aluminum with added manganese to increase its strength 20 stronger than the 1100 grade. It has good resistance to marine atmosphere and salt water corrosion.

It has excellent corrosion resistance and workability. This alloy is non heat treatable and is corrosion resistant. Aluminum sheet aluminum sheet metal comes in a variety of thicknesses and weights in many different grades. It is commonly used in the transportation food and aerospace industry due to its light weight and resistance to corrosion.

Ryerson offers heat treatable aluminum sheet grades like the popular 6061 aluminum alloy that can be used for commercial applications that require strength corrosion resistance and machinability as well as non heat treatable grades when formability and weldability are priorities. Its resistance to fatigue is better than most grades of aluminum. This grade can be deep drawn or spun welded or brazed. A letter representing temper follows the first four digits to indicate if the material is supplied already work hardened h or heat treated t or annealed o at the mill.

This is the highest strength alloy of the non heat treatable grades.