Aluminum 6061 Bend Radius Sheet Metal

Specifing a bend radius from here will help prevent hair line cracks.

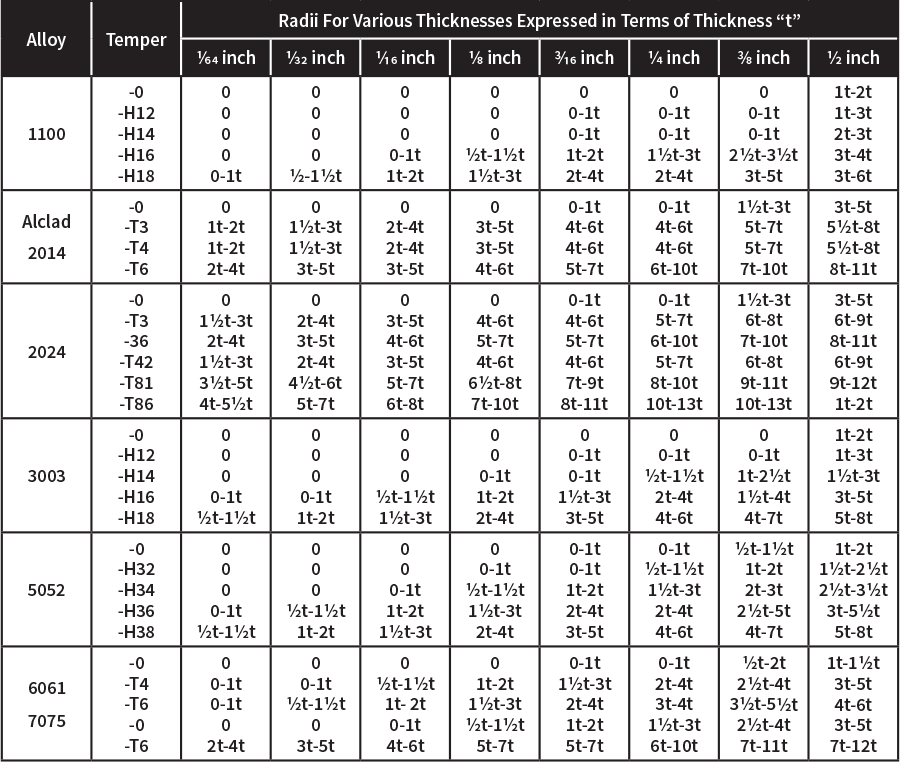

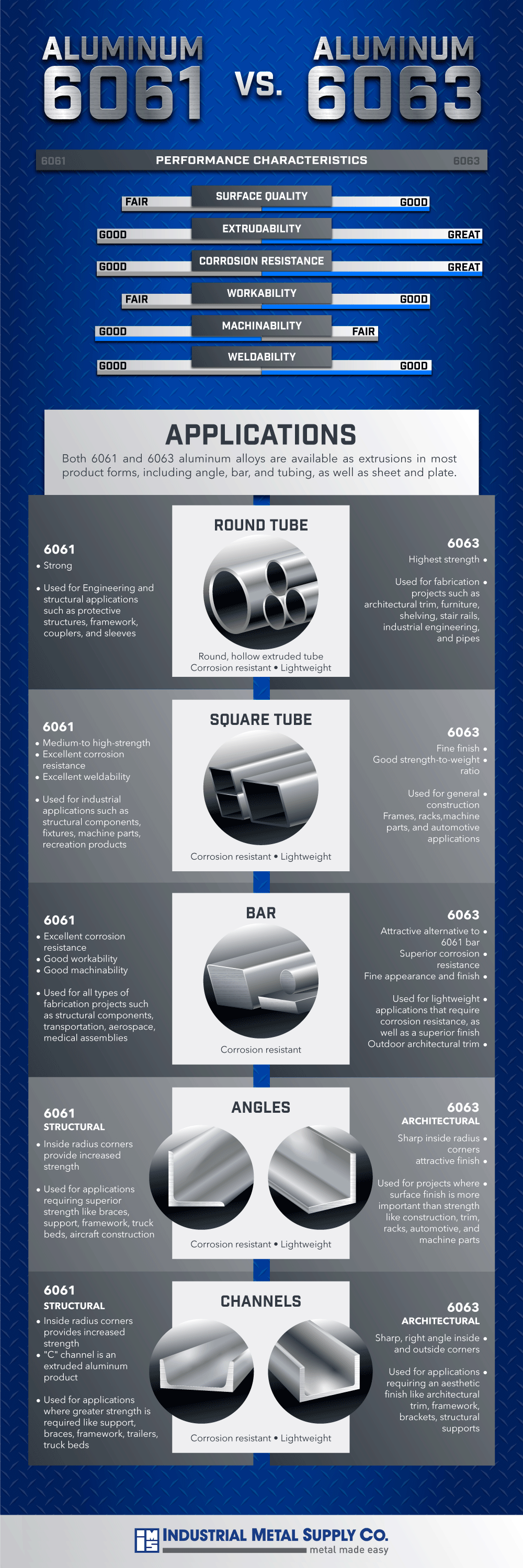

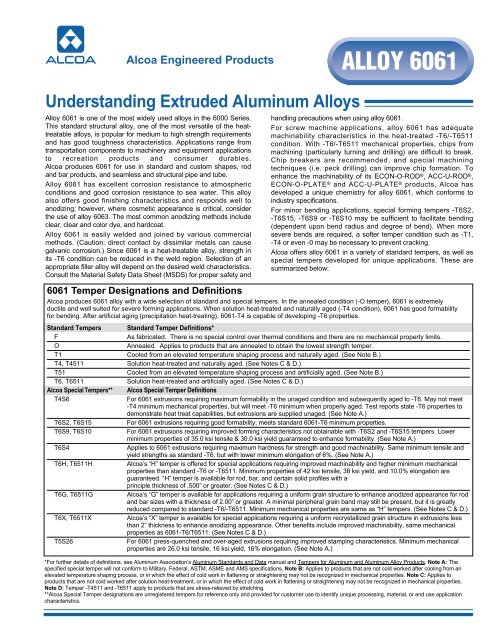

Aluminum 6061 bend radius sheet metal. 6061 t3 is not recommended for sheet metal work because it will crack on the outside radius once it passes its yield when being processed on a brake press for example. Or yor metal ees 0 9 rier ane p bo ermanton 0 00 99 99 90 fa 90 zzzaicmetalcom 6061 alloy. 3003 0 1100 0 6061 s0 5052 s0. The bend radii listed are standard minimum if manufacturing for aircraft and aerospace applications.

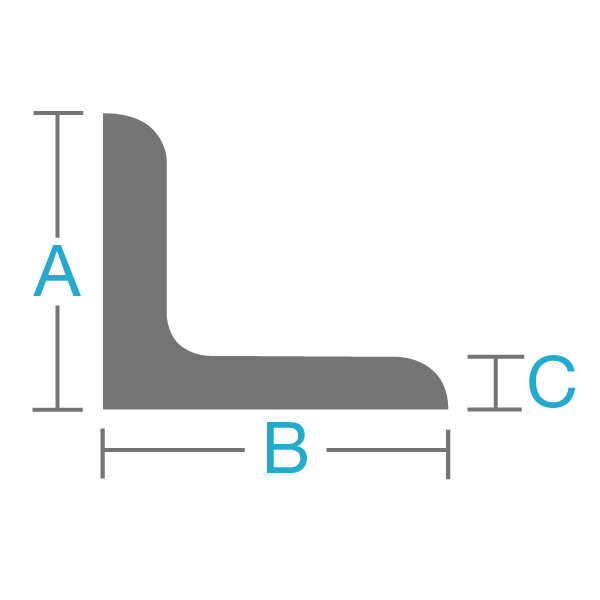

The bend radius you select may not be available if the geometry of the part will not allow us to bend with the specific tooling required to achieve that radius. If your bend radius needs to be adjusted a member of engineering design services team will contact you before your design is manufactured. Say you get a print that says you need to bend a part to an external angle of 100 degrees that s an internal angle of just 80 degrees. Per the aluminum association inc.

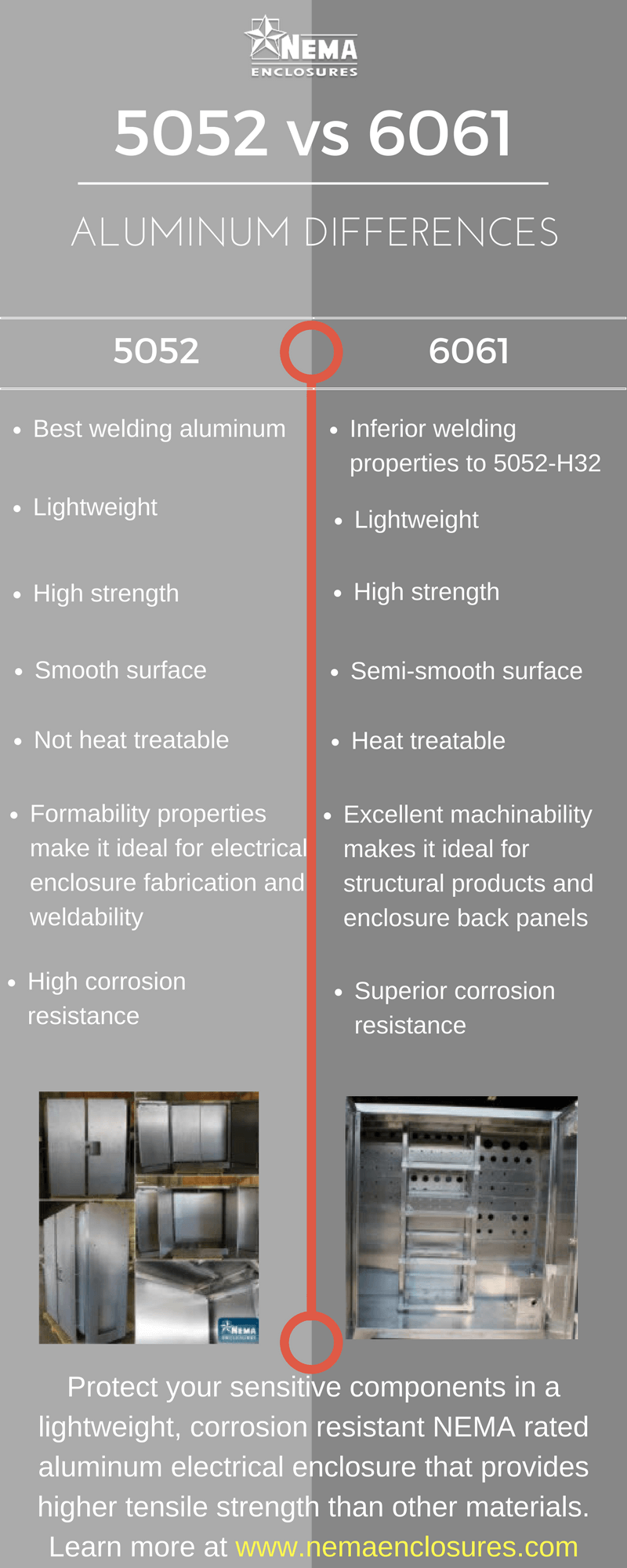

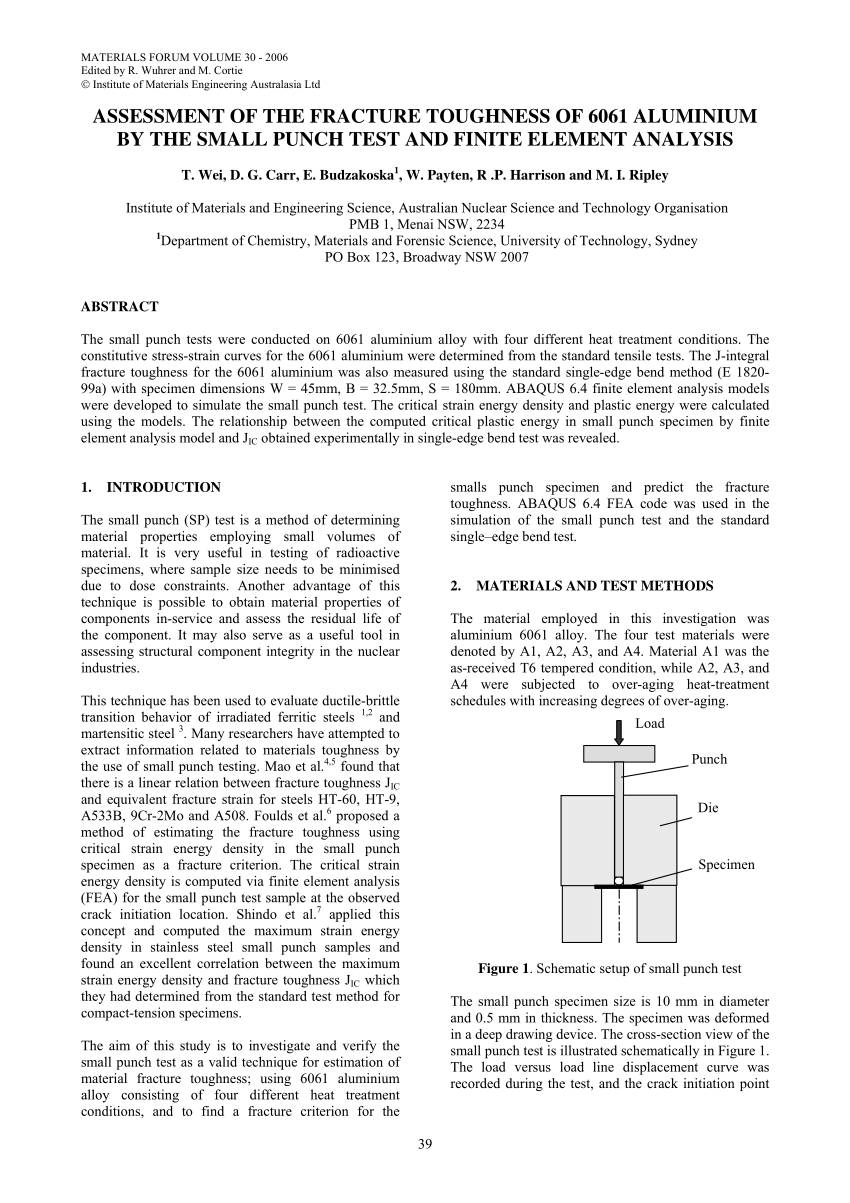

From non heat treatable 3003 and 5052 to the heat treatable 2024 6061 and 7075 you have many options from which to choose. Still if you want to avoid cracking abide by the minimum bend radius in 0 25 in thick 6061 t6 which is quite large see figure 3 and avoid bending acute angles. 6061 t6 is the most commonly used aluminum alloys. Recommended minimum bend radii for 90 degree cold forming of sheet plate.

Sheet metal bend radii if these guidelines are not followed more research and or some form of analysis may be requried. Material suppliers have tables that show the approximate minimum inside bend radius for the various alloys the temper condition of each and the minimum allowable inside radius at 90 degrees of bend angle. Here the alloy is 6061 and the temper is t6 meaning the alloy has been thermally treated. 2024 t3 1020 1025 4130 ann.

But the question remains the same which alloy is the best product for bending. 6061 t6 2 3 3 4 6 8 18 32 aluminum minimum bend radius in 1 32nds of an inch title. Radii for various thicknesses expressed in terms of thickness t. Since commercial sheet metal bending can be done with less concern for stresses caused during forming operation the radius can be near zero for thin sheet metal.

Recommended minimum bend radii for steel and aluminum. The main alloy ingredients are magnesium and silicon. Minimum bend radius xls author.