Aluminium 6061 Data Sheet

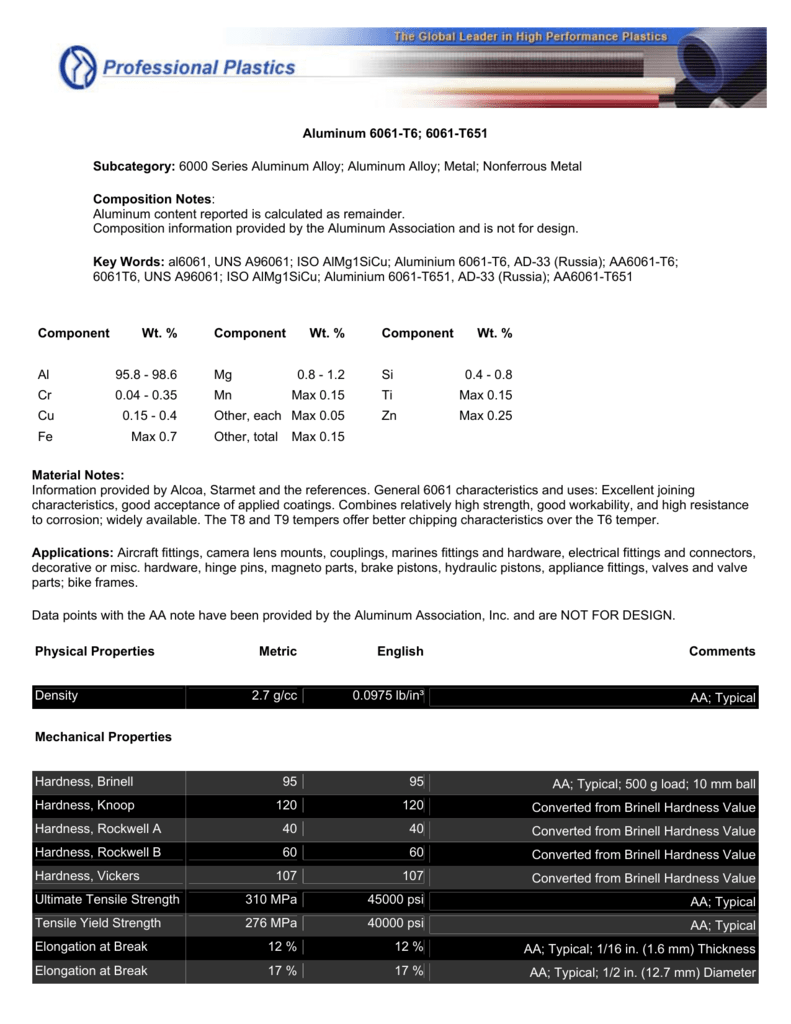

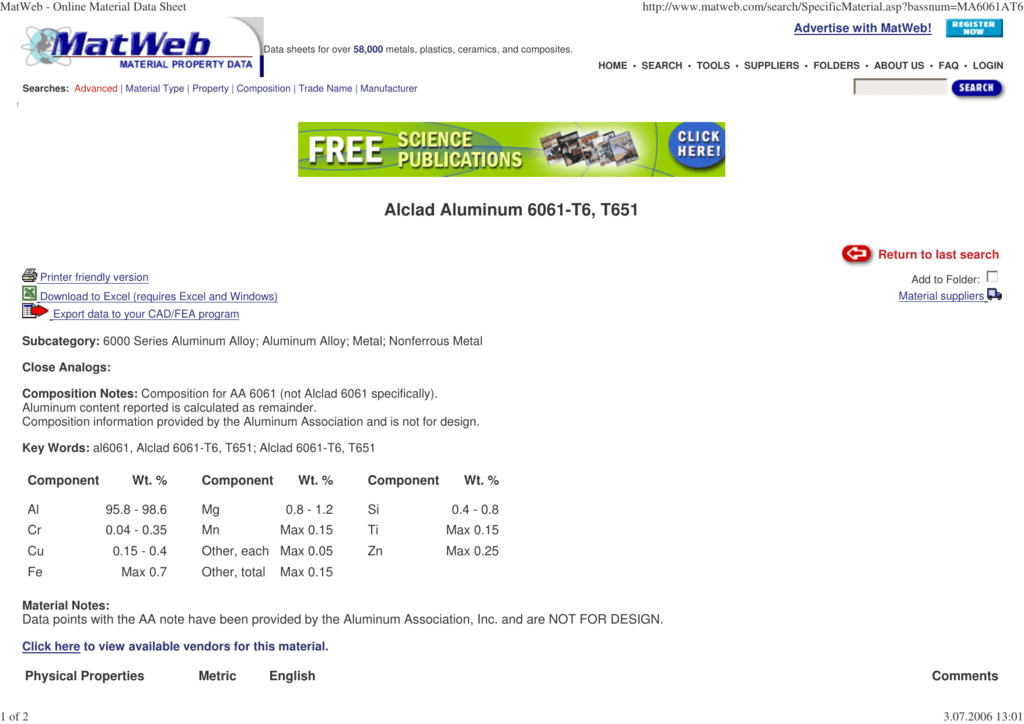

Composition information provided by the aluminum association and is not for design.

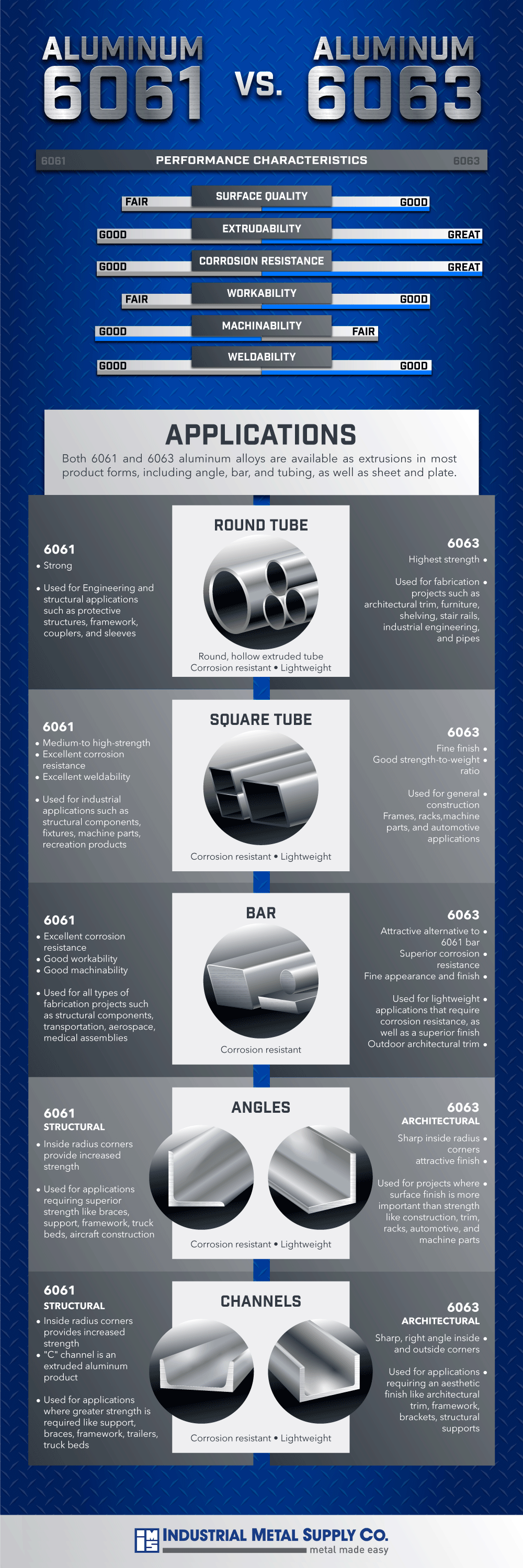

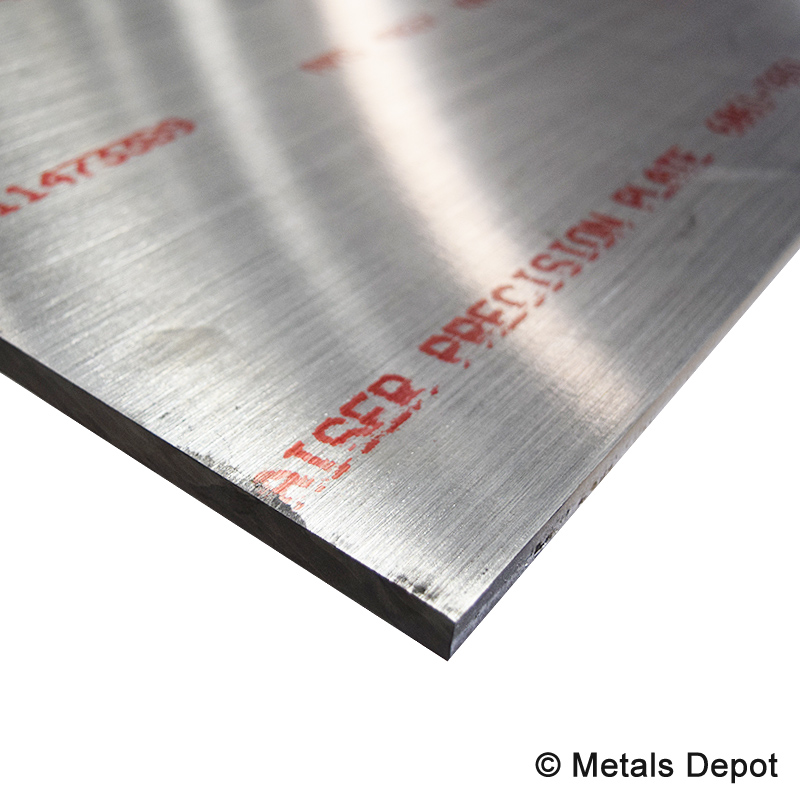

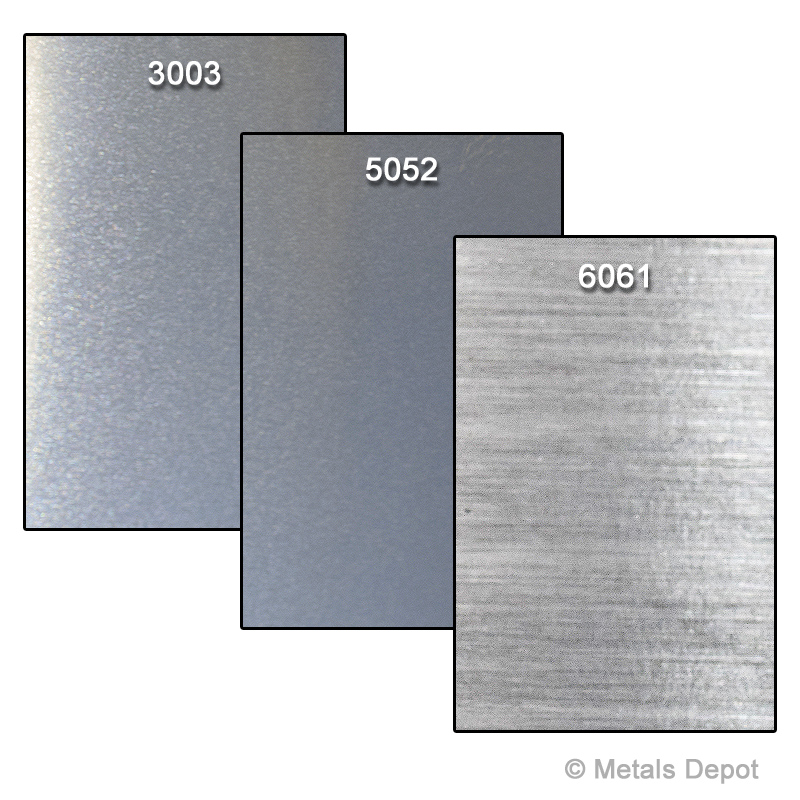

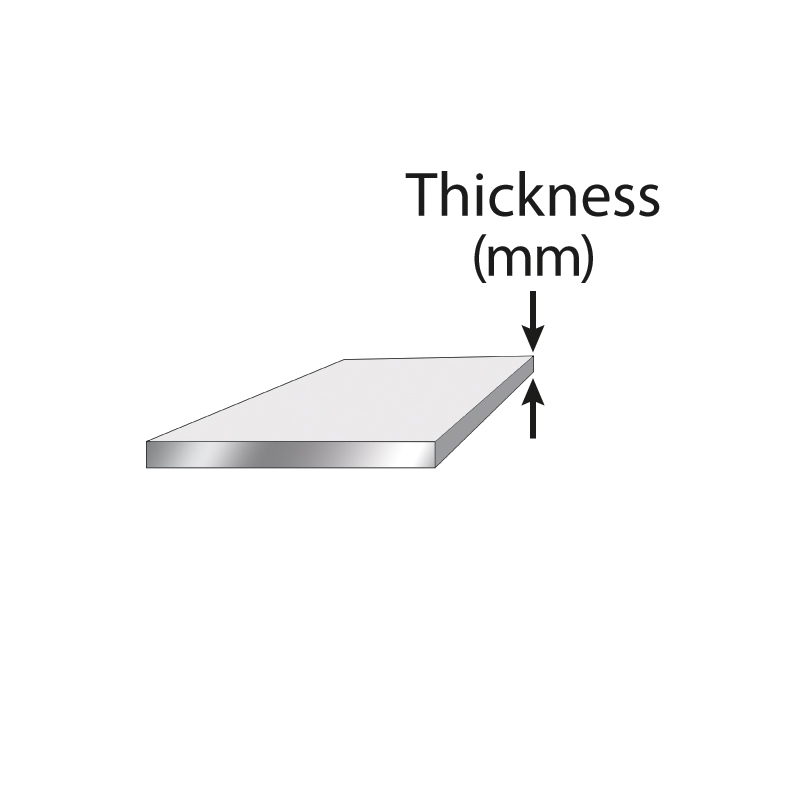

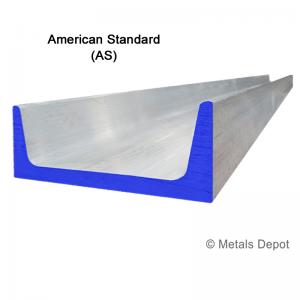

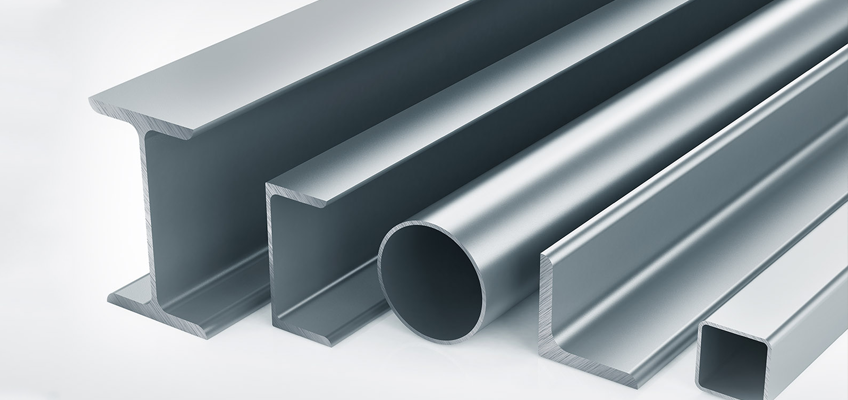

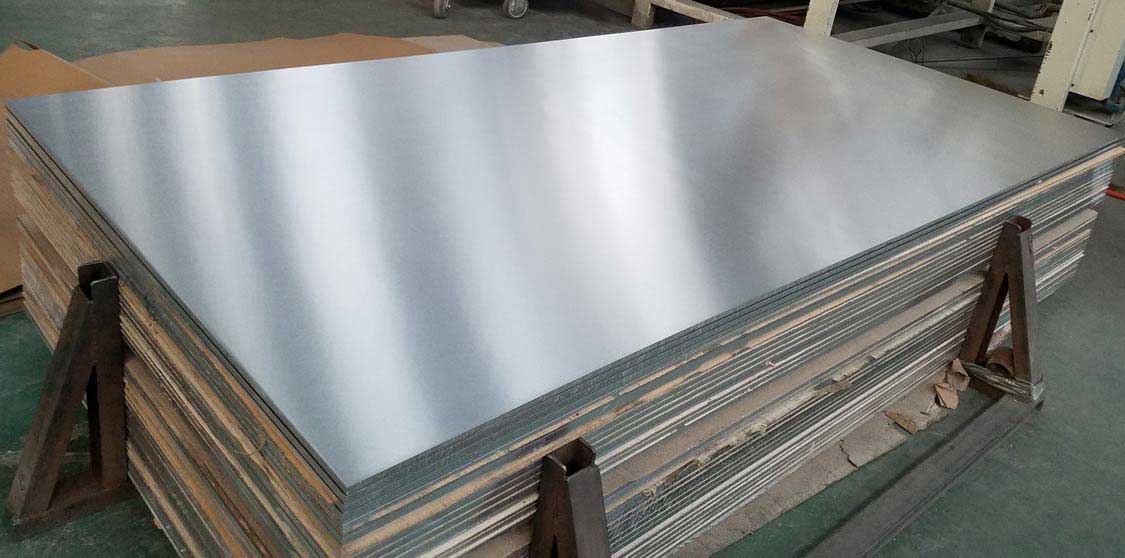

Aluminium 6061 data sheet. It is one of the most widely used alloys. 6061 commercial aluminium alloy which is available in sheet plate and extrusions offers medium to high strength. General 6061 characteristics and uses. It has medium fatigue strength.

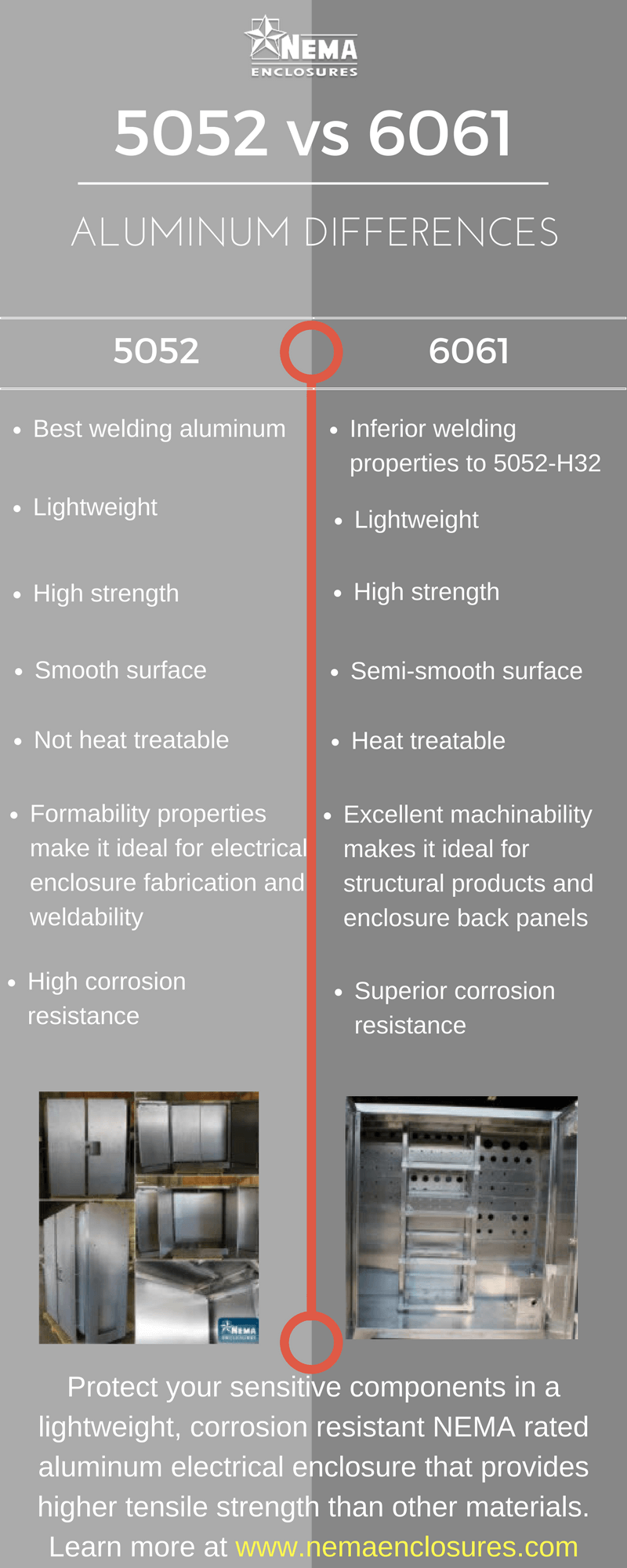

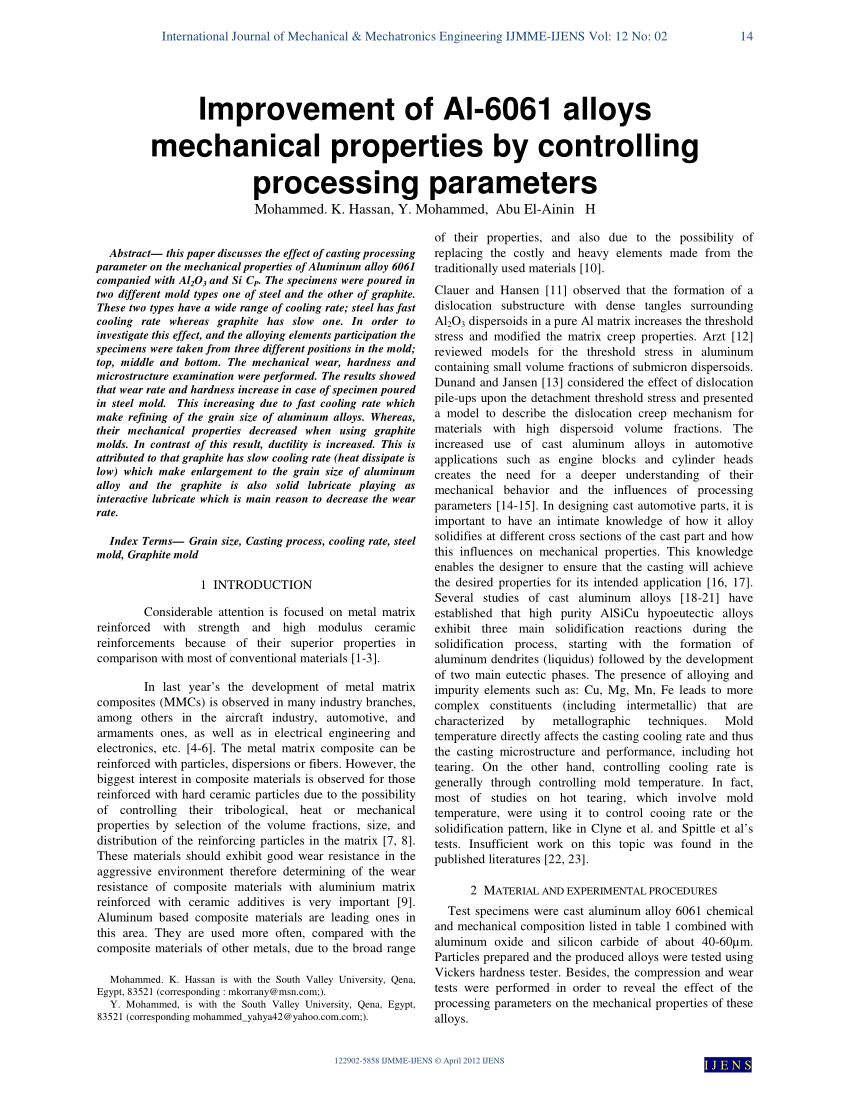

The main alloying elements are magnesium mg and silicon si. It has very good corrosion resistance and very good weldability although reduced strength in the weld zone. Combines relatively high strength good workability and high resistance to corrosion. 6061 can be heat treated.

6061 is a precipitation hardening alloy containing magnesium and silicon as its major alloying elements. 6061 uns designation a96061 is a precipitation hardened aluminum alloy containing magnesium and silicon as its major alloying elements. It is typically used in heavy duty applications. It is one of the most common alloys for general purpose use.

The t8 and t9 tempers offer better chipping characteristics over the t6 temper. Consult the material safety data sheet msds for proper safety and handling precautions when using alloy 6061. It has very good corrosion resistance and very good weldability although reduced strength in the weld zone. It has good cold formability in the temper t4 but limited formability in t6 temper.

Since 6061 is a heat treatable alloy strength in its t6 condition can be reduced in the weld region. Technical data sheet aluminum 6061 is an extremely versatile heat treatable aluminum alloy due to its content of silicon and magnesium. Al 6061 aluminum alloy is a general purpose structural alloy developed by alcoa in 1935. Aluminium alloy 6061 is a medium to high strength heat treatable alloy with a strength higher than 6005a.

Originally called alloy 61s it was developed in 1935. 6000 series aluminum alloy. It has medium fatigue strength. Excellent joining characteristics good acceptance of applied coatings.

It has good cold formability in the temper t4 but limited formability in t6 temper. Nonferrous metal close analogs. The temper designations mainly have 6061 t4 t451 al 6061 t6 6061 t651 etc. Originally called alloy 61s it was developed in 1935.

6061 has a wide range of mechanical and corrosion resistance properties as well as having most of the good qualities of aluminum. It is a heat treatable alloy with medium fatigue strength and very good corrosion resistance. It has good mechanical properties and exhibits good weldability. Aluminum content reported is calculated as remainder.