Aircraft Sheet Metal Patch Repair Procedure

Sheet metal fabrication is considered a blend of art and science requiring finesse to achieve desirable results.

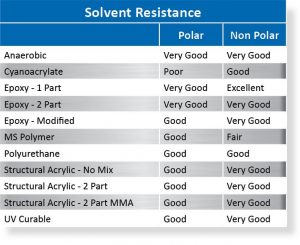

Aircraft sheet metal patch repair procedure. Control parts wing covering or similar parts of the aircraft. Maintain the original strength. It is directly applicable to the repair being made. September 1994 subcourse overview this subcourse is designed to provide you with a general familiarization of the airframe of today s aircraft and repair procedures.

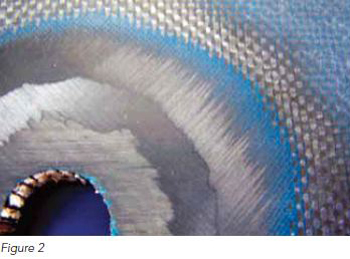

When repair of a damaged part is possible first study the part carefully to fully understand its purpose or function. The repair data may also be used as approved data and the ac chapter page and paragraph listed in block 8 of faa form 337 when. Maintain the original strength. Basic principles of sheet metal repair.

Fabricate a doubler of the same material but one size thicker than the part being repaired. The user has determined that it is appropriate to the product being repaired. Place a splice where the member is. It is not contrary to manufacturer s data.

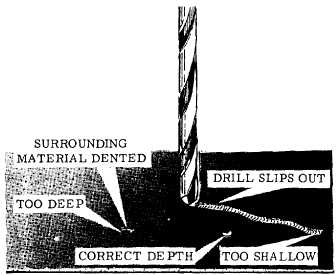

Basic airframe repair subcourse number al0992 edition a us army aviation logistics school fort eustis virginia 23604 5439 4 credit hours edition date. The art of sheet metal repair. In spect rivet joints adjacent to damaged structure for partial failure by removing one or more. If the rivet is too long the formed head will be too large or the rivet may bend or.

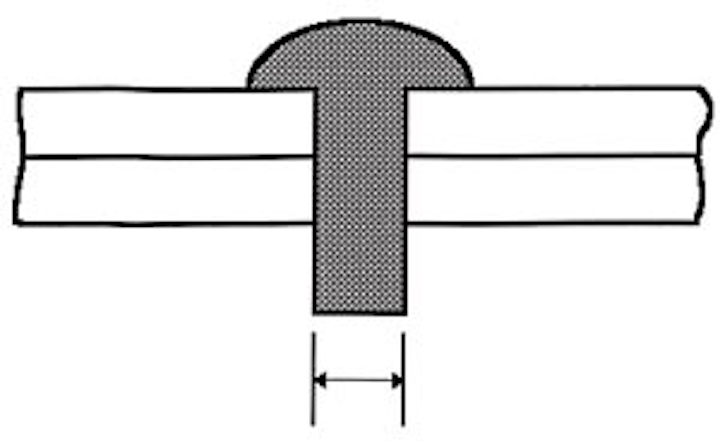

The patch plate should have a cross sectional area equal to or greater than that of the original damage. Minimum rivet diameter is equal to the thickness of the thickest sheet to be riveted. Sometimes the experience to achieve the desirable results can be costly. Supported metal skin support the sheet metal on the inside with a bucking bar.

Principal requirements in repair of structures inspection of the damage and accurate estimate of the type of repair required important steps in repairing structural damage. The diameter will depend on the number of rows of rivets you re planning on installing. The resources and approved data vary by aircraft and operation but generally include the manufacturer s structural repair manual maintenance manual and ac. Aircraft sheet metal work prem mahendranathan structural repair.

Maximum rivet diameter is three times the thickness of the thickest sheet to be riveted. The doubler should be of a. Debur the outer edge of the patch. Stop drill the crack ends with a no.

Attach the doubler to the part with clamps and drill holes. The proper length of rivet is an important part of the repair.